Menu

Sign up for our Newsletter.

Sign up for our Newsletter.

Finish Options

Limitless choices to customize your selections.

No compromises! You get the benefit of our commitment to offering a wide array of finish options. Our standard finishes meet most project needs and provide a great match for much existing woodwork. Plus, our limitless custom finish choices mean you can offer a truly unique end product or match any established color pallet. Choose a wood, stain or paint and hand-applied glaze combination for one-of-a-kind interior design. If you have a finish in mind, contact our artisans and let us turn inspiration into a beautiful custom creation.

Please remember that all finishes shown on this site are representative and may not be an exact match to the finish on actual products. Other wood species, finishes, and profiles are available in addition to those shown.

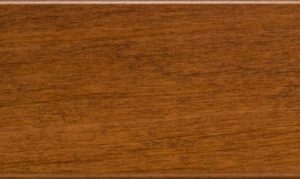

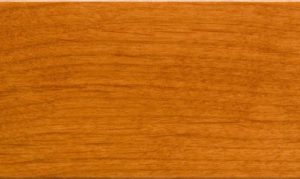

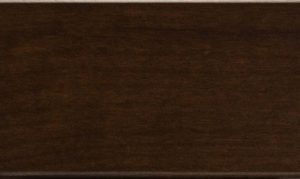

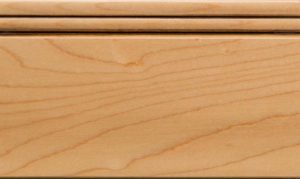

Stained Finish

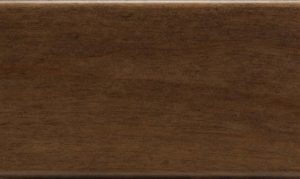

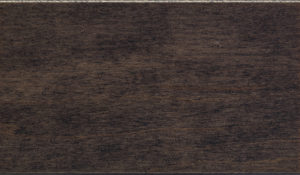

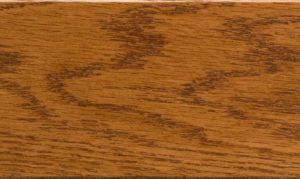

All of our stains are formulated for spray application. We offer 19 hand-wiped stain colors as well as custom stain matching capabilities. Real wood products will vary in color and graining so, as an industry standard, it is considered acceptable to have a certain degree of variation between a color sample and the actual finished product.

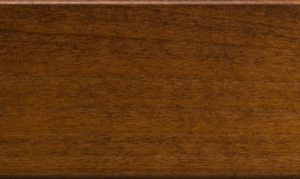

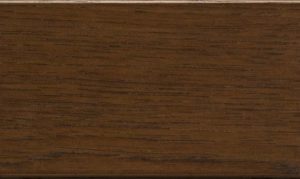

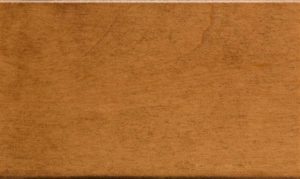

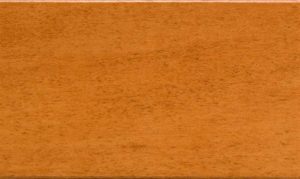

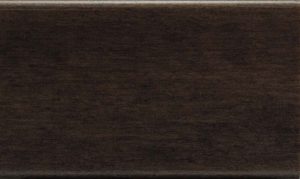

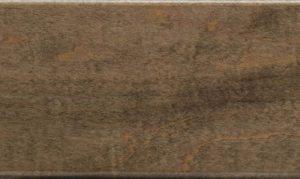

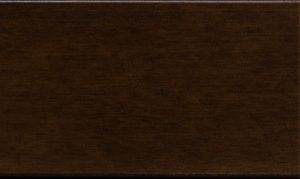

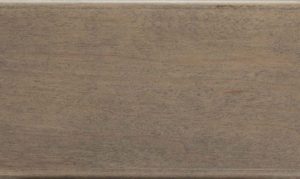

Alder

Acorn

Alder

Autumn Wheat

Alder

Carmel

Alder

Chestnut

Alder

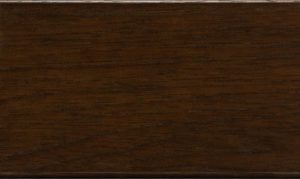

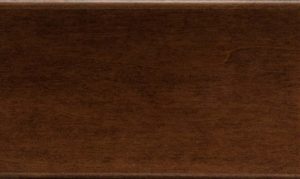

Dark Pecan

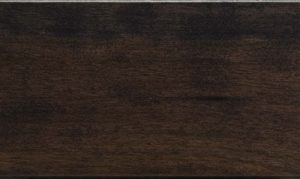

Alder

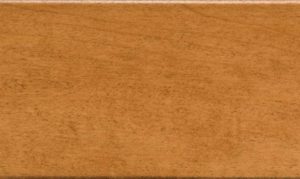

Harvest

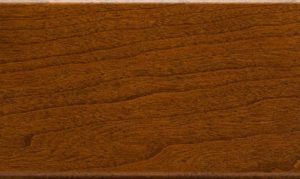

Alder

Honey Maple

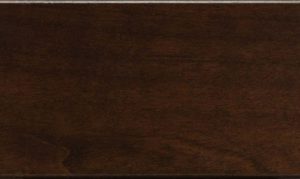

Alder

Natural

Alder

Woodstock

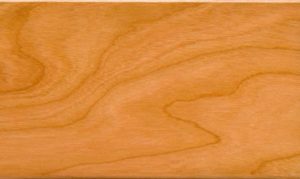

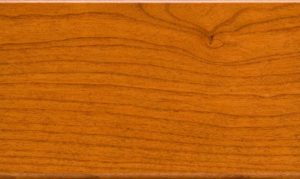

Cherry

Autumn Wheat

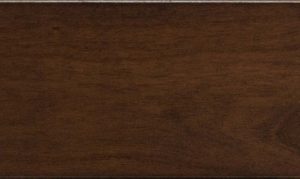

Cherry

Brandy

Cherry

Cascade

Cherry

Chestnut

Cherry

Dark Pecan

Cherry

Natural

Cherry

Riverwood

Cherry

Rocky Road

Cherry

Wild Cherry

Cherry

Woodstock

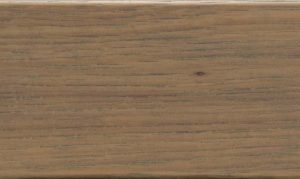

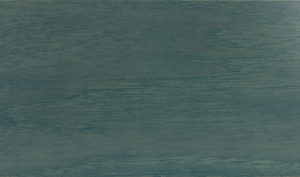

Hickory

Autumn Wheat

Hickory

Beechwood

Hickory

Brandy

Hickory

Carmel

Hickory

Dark Pecan

Hickory

Driftwood

Hickory

Emerald

Hickory

Natural

Hickory

Oceanside

Hickory

Slate

Hickory

Riverwood

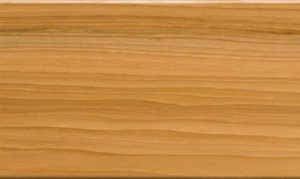

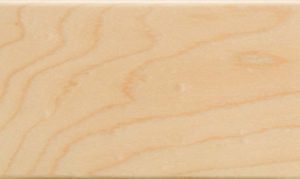

Maple

Acorn

Maple

Autumn Wheat

Maple

Carmel

Maple

Cascade

Maple

Classic Grey

Maple

Dark Pecan

Maple

Driftwood

Maple

Emerald

Maple

Harvest

Maple

Honey Maple

Maple

Java

Maple

Lava Stone

Maple

Natural

Maple

Oceanside

Maple

Riverwood

Maple

Slate

Maple

Spicewood

Maple

Woodstock

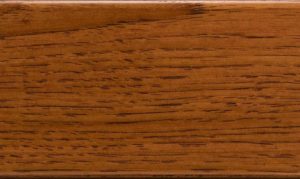

Oak

Acorn

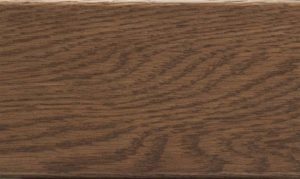

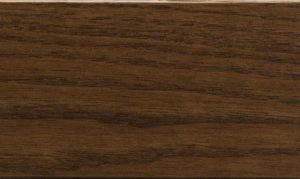

Oak

Autumn Wheat

Oak

Brandy

Oak

Carmel

Oak

Cascade

Oak

Charcoal

Oak

Chestnut

Oak

Dark Pecan

Oak

Driftwood

Oak

Lava Stone

Oak

Natural

Oak

Riverwood

Oak

Rocky Road

Oak

Slate

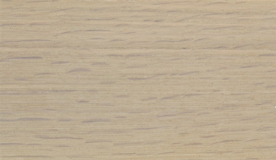

Oak White - Rift

Acorn

Oak White - Rift

Autumn Wheat

Oak White - Rift

Cascade

Oak White - Rift

Driftwood

Oak White - Rift

Emerald

Oak White - Rift

Lava Stone

Oak White - Rift

Linen

Oak White - Rift

Natural

Oak White - Rift

Oceanside

Oak White - Rift

River Rock

Oak White - Rift

Riverwood

Oak White - Rift

Rocky Road

Oak White - Rift

Slate

Oak White - Rift

Woodstock

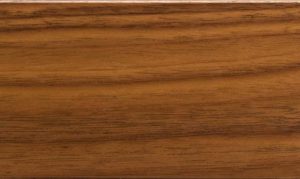

Walnut

Natural

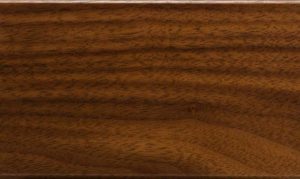

Walnut

Autumn Wheat

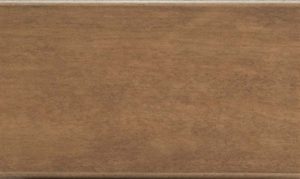

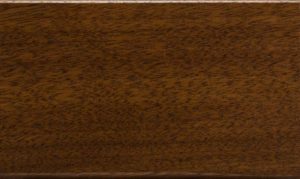

Walnut

Brownstone

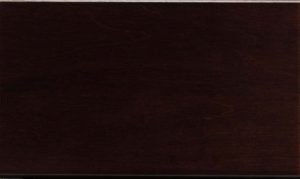

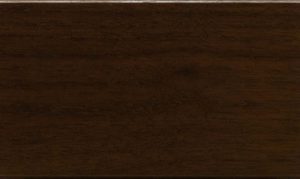

Walnut

Dark Pecan

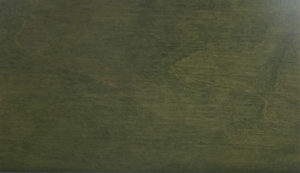

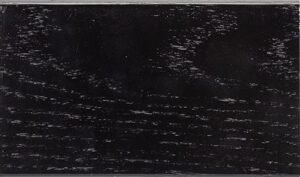

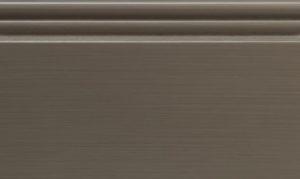

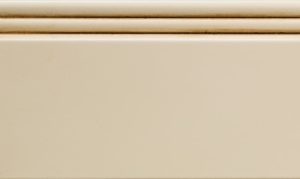

Painted Finish

All of our paints are formulated for spray application. We offer 18 standard paint colors as well as custom paint matching capabilities.

Painted Finish

Alabaster

Painted Finish

Almond

Painted Finish

Atlantic Blue

Painted Finish

Cobblestone

Painted Finish

Country White

Painted Finish

Desert Sand

Painted Finish

Ebony

Painted Finish

Eggshell

Painted Finish

Evergreen

Painted Finish

Fieldstone

Painted Finish

Frost

Painted Finish

Graphite

Painted Finish

Harbor Blue

Painted Finish

Harbor Grey

Painted Finish

Hearthstone

Painted Finish

Indigo

Painted Finish

Ivory

Painted Finish

Meadow

Painted Finish

Mushroom

Painted Finish

Nightfall

Painted Finish

Olive

Painted Finish

Rainforest

Painted Finish

Snow White

Painted Finish

Stonegate

Painted Finish

Stormy Blue

Painted Finish

White Sky

Painted Finish

Winter White

Painted Finish

Woodland Grey

Glazed

Available in brown or black. After stain or paint is applied, the glaze is applied to the entire surface on the face side of the item and then either wiped off or brushed by hand to change the overall look of the stain or paint color underneath. Although we have a standard application process for glazing, it is a process that is done by hand and is somewhat artistic. Therefore, each glazed piece will have a unique look. We strongly recommend that a sample door is ordered in the door style and profiles that will be used for the project as each profile will take the glaze differently.

Cherry

Autumn Wheat Brown Glaze

Hard White Maple

Autumn Wheat Black Glaze

Hard White Maple

Autumn Wheat Brown Glaze

Hard White Maple

Harvest Black Glaze

Hard White Maple

Natural Brown Glaze

Paint

Cobblestone Brushed Black Glaze

Paint

Eggshell Brown Glaze

Paint

Eggshell Brushed Brown Glaze

Paint

Eggshell Black Glaze

Paint

Eggshell Brushed Black Glaze

Paint

Fieldstone Brushed Black Glaze

Paint

Hearthstone Brushed Black Glaze

Paint

Snow White Brown Glaze

Paint

Snow White Brushed Brown Glaze

Custom Matched Finishes

We can custom match almost any stain or paint color to a sample you provide. The stain sample you provide should be on the wood species required for the match. If we are matching a paint color, we may be able to reference the color from the manufacturer’s color name and identification number. If not, we will require that you provide us with an actual painted sample in order for us to formulate the color. The color sample will generally be shipped to you within 5 business days.

Vintage Finish

Available on stained products. The item is first stained using your specified color then the face side is covered entirely with a black stain and rubbed off randomly to reveal the stained surface beneath. We require that a sample door be ordered with each job for customer approval.

Brushed Glaze

Available as a standard finish on painted products only. The glaze will be sprayed on and brushed leaving a subtle, even coat of glaze on the face side of the item. Not all brushed glazes are available on all paint colors, so please check the pre-finish price table to see if the paint/brushed glaze combination you want is a standard combination for us. We will require that a sample door be ordered for all non-standard finish combinations for approval.

Distressing

Expert distressing adds character, warmth and charm to solid wood cabinets and drawer fronts. Our unique method means you can select the technique and level of distressing you prefer on your solid wood product. The distressed marks you choose are placed randomly on the face of the solid wood to achieve an aged appearance.

Hand Wiped Glaze

Available on stained or painted products, the glaze is sprayed on and wiped off with a soft cloth leaving behind traces of glaze in the corners and profiled areas. Using more detailed profiles allows for more of the glazing to remain after being wiped.

Not all hand wiped glazes are available on all stain and paint colors, so please check the pre-finish price table to see if the stain/glaze combination you want is a standard combination for us. We will require that a sample door be ordered for all non-standard finish combinations for approval.

Distressing Techniques

1. Nicks, Dents, Screw Marks: Technique of striking the entire wood surface randomly with tools to create the effect of wear over time.

2. Corner Wear: Sanding technique used to soften the corners of door frames and panels before finish is applied.

3. Worm Holes: Random placement of small round divots in wood creating the effect of insect penetrations that naturally occur in wood.

4. Simulated Cracks: Hand made slits following the direction of the grain placed toward the outer panel edges and frames. Simulated cracks appear on some but not all pieces with some parts having more than one in various lengths for a natural look.

5. Rasping: This technique will randomly place marks on the raised profiles and outside edges to simulate severe wear.

6. Heirloom Rub-Thru: The profiles on the face side are rubbed through to expose the raw wood underneath simulating natural wear that would occur over time.

Our Finish Process

Real wood’s natural beauty is revealed during the finishing process. The stain color you select, combined with the grade of the wood species, affects the overall look of the finished product. Each wood species has characteristics that make it unique from all others. Unless otherwise specified, your order will be made using our Standard Grade wood.

• All stained products are hand-wiped unless otherwise noted and top-coated using a catalyzed conversion varnish with UV inhibitor added to protect against discoloration.

• We offer two gloss finishes: Satin (30-35 sheen) or Matte (15-20 sheen).

• Due to the nature of wood, there will be a certain degree of color and grain variation between the color sample and the finished product. These variations are considered natural characteristics of wood and are standard throughout the industry.

• We recommend a post-catalyzed, solvent based enamel primer when using our paint.

845 Prosper Street De Pere, WI 54115

Toll Free: 888.815.9648

Fax: 920.336.5956

©2024 Valley Custom Door®